Solutions for Wearable Applications

Wearable Applications

As a global technology leader, Research Adhesives (AR) provides skin adhesion, connectivity, device assembly, and attachment solutions for a wide range of wearable monitoring, rehabilitation, and medical device applications, including ECG (Electrocardiography), skin temperature, respiration, pulse, blood pressure, body kinematics, glucose levels, and insulin

dispensing.

Our chemists and engineers are passionate about developing innovation-rich products that help our customers overcome challenging applications in meeting the demands of an ever-evolving wearables market.

Device design and assembly

Conductive bonding

Highly conductive transfer and double-coated tapes to solve X, Y, and Z-axis interconnection challenges for biosensors, defibrillators, and other electronics applications within a wearable device.

Device assembly

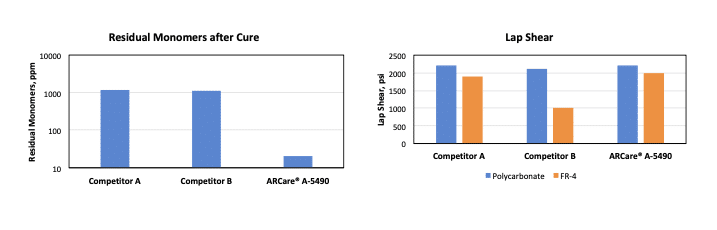

UV-curable liquid adhesives are designed for bonding to a wide variety of plastic, metal, and FR4 substrates. This patented technology minimizes residual monomers post-cure, enhancing biocompatibility and reducing the risk of skin irritation, making it ideal for the rapid assembly of medical sensors and wearable devices.

Space Management

Double-coated spacer tapes are used in biosensor devices to create channels with tailorable volumes and flow rates, accommodating a variety of substrate chemistries and surface energies. Our advanced manufacturing process, coupled with in-line measurement gauges, ensures precision in tape thickness and adhesive performance, guaranteeing optimal device functionality.

Process aids

Ultra-clean release liners and protective films to withstand extreme process conditions for medical device production with no chemical contamination.

Device attachment and skin bonding

Device attachment

Medical-grade device attachment tapes bond effectively to low surface energy (LSE) substrates like thermoplastic elastomers (TPE) without secondary curing, streamlining production by eliminating complex steps and specialized equipment. This simplicity and versatile application make these tapes an advantageous alternative to methods like heat staking or ultrasonic welding.

Skin bonding

Skin-friendly adhesives are specifically engineered for optimal compatibility with skin, offering adjustable wear times from a few hours up to 28 days. These advanced adhesive technologies are ideal for a range of wearable devices, from medical monitors to fitness trackers, providing comfort and reliability for extended wear.

Types of Tape Construction

Transfer Tape (TT)

Unsupported adhesive is coated directly onto a release liner, allowing transfer films to be the most flexible and conformable of all bonding systems.

Single-Coated Tape (SCT)

Single-coated tapes consist of a backing that is coated on one side with an adhesive. Single-coated tapes are available either in selfwound rolls or with a release liner for ease of application.

Heat-activated Film Tape

Heat-activated film tapes require heat and pressure to achieve final bonding to any surface.

Double- Coated Tape (DCT)

Double-coated tapes have a carrier that is coated on both sides with an adhesive. The instant bonding capabilities of double-coated tapes make them very conductive to automation and high-speed processing.

Technology Highlights

Device assembly – UV curable liquid adhesive

ARcare® A-5490

Key features:

Uncured Properties

| Solvent | Appearance | Density, g/ml | Viscosity, cPS | Lap shear to polycarbonate, PSI | Moisture permeability (g-ml/m2-day) |

|---|---|---|---|---|---|

| No Reactive Solvents | Liquid Yellow Liquid-Gel | 1.10 | 5000-8000 | ~ 2000 ps1 | >500 |

Performance comparison:

Technology Highlights

Skin bonding – Medium-term wear

ARcare® 94220

Key features:

Product construction:

| Construction | 1st Release Liner (Type/Thickness) | 1st Adhesive (Type/Thickness) | Carrier/Backing (Color/Type/Thickness or Basis Weight) | Peel Adhesion to Stainless Steel (ozf/in[N/25.4 mm]) | Moisture permeability (g-mil/m2-day) |

|---|---|---|---|---|---|

| SCT | Yellow/paper/81 μm | Acrylic skin/66 μm | Non-woven polyester/279μm | 55/15.3 | >500 |

Technical properties:

| Peel Adhesion on Stainless Steel | Release of Polyester Liner | Moisture vapor transmission | Recommended storage of unconverted product | Shelf life of unconverted product |

|---|---|---|---|---|

| 55 oz/inch 15 n/25mm | 70 g/2” | >500 g/m2/day | 270°F±20°F 21°C ±11°C 50% ± 20% RH |

Not to exceed one year from the date of manufacture |

Skin bonding – Wear times

Available in three categories – short, medium, and long-term wear, our skin-friendly adhesives offer an unparalleled selection in both breadth and depth of product. This selection allows you to choose the right adhesive for your application. Our products are designed to maximize performance including the ability to withstand the daily impacts of every-day use and reduced residue around the device.

The chart to the right shows our skin-bonding portfolio with each product family aligned by wear time. Please see the Adhesives Guide section for more technical information.

Wear times are estimated by Adhesives Research internal studies and may not fully reflect the actual end-use performance. Wear times can vary based on factors such as device weight, size, shape, and environmental conditions. It is strongly recommended that customers conduct their own studies using specific medical device design to ensure accurate wear time assessments.

Skin Bonding

| Product | Description | Construction | 1st Release Liner (Type/Thickness) | 1st Adhesive (Type/Thickness) | Carrier/Backing (Color/Type/Thickness) | 2nd Adhesive (Type/Thickness) | 2nd Release Liner (Type/Thickness) | Peel Adhesion to Stainless Steel (ozf/in [N/25.4mm]) | Moisture Permeability (g-mil/m2-day) |

|---|---|---|---|---|---|---|---|---|---|

| ARcare® 93996 | Acrylic PSA for short-term wear applications | SCT | Ream siliconized polycoated paper / 87# | Rubber skin / 51 µm | Embossed polyethylene film / 74 μm | – | – | – | – |

| ARcare® 93256 | Acrylic PSA for short-term wear applications | SCT | Clear polyester / 51 μm | Acrylic skin / 71 μm | Clear polyurethane / 86 μm | – | – | 5 (1.4) | > 160 |

| ARcare® 93276 | Acrylic PSA for short-term wear applications | SCT | Clear polyester / 51 μm | Acrylic skin / 71 μm | White polyester non-woven / 279 μm | – | – | 5 (1.4) | – |

| ARcare® 94579 | Acrylic PSA for short-term wear applications | DCT | White polyester / 51 μm | Acrylic skin / 71 μm | White polyester non-woven / 279 μm | Acrylic device / 51μm | Clear polyester / 51 μm | 5 (1.4) / 60 (16.7) | > 480 |

| ARcare® 7717 | Acrylic PSA for short-to-medium term wear applications | SCT | White paper / 84# / 160 μm | Acrylic skin / 61 μm | White cross-linked EVA foam / 4# / 1588 μm | – | – | 81 (22.5) | – |

| ARcare® 7261 | Acrylic PSA for short-to-medium term wear | SCT | Off-white paper / 55# / 81 μm | Acrylic skin / 43 μm | White polyester-woven / 381 μm | – | – | – | – |

| ARcare® 8311 | Acrylic PSA for-to-medium term wear applications | SCT | Off-white paper / 55# / 81 μm | Acrylic skin / 15 μm | Clear polyurthane / 25 μm | – | – | 18 (5.0) | > 900 |

| ARcare® 94220 | Acrylic PSA for medium-term wear applications | SCT | Yellow paper/White paper/ 53# / 81 μm | Acrylic skin / 66 μm | White polyester non-woven / 279 μm | – | – | 55 (15.3) | > 500 |

| ARcare® 93752 | Acrylic PSA for long-term wear applications | SCT | Clear polyester / 51 μm | Acrylic skin / 74 μm | White polyrethane non-woven / 220 μm | – | – | 37 (10.3) | 550 |

| ARcare® 93439 | Acrylic PSA for long-term wear applications | SCT | Clear polyester / 51 μm | Acrylic skin / 66 μm | White polyester non-woven / 279 μm | – | – | 90 (25.0) | 550 |

| ARcare® 93945 | Acrylic PSA for long-term wear applications | SCT | Clear polyester / 51 μm | Acrylic skin / 74 μm | Clear polyurethane/ 51 μm | supported on White paper / 122 μm | – | – | 74 (20.6) | 490 |

| ARcare® 51000 | Acrylic PSA for long-term wear applications | SCT | Siliconized paper | Acrylic skin / 76 μm | White polyurethane non-woven / 127 μm | – | – | 24 (6.7) | > 675 |

| ARcare® 93690 | Acrylic PSA for long-term wear applications | SCT | Clear polyester / 51 μm | Acrylic skin / 76 μm | White polyurethane non-woven / 127 μm | – | – | 24 (6.7) | > 675 |

Device Attachment

| Product | Description | Construction | 1st Release Liner (Type/Thickness) | 1st Adhesive (Type/Thickness) | Carrier/Backing (Color/Type/Thickness) | 2nd Adhesive (Type/Thickness) | 2nd Release Liner (Type/Thickness) | 1st Adhesive Peel Adhesion to Stainless Steel (ozf/ in [N/25.4mm]) | 2nd Adhesive Peel Adhesion to Steel (ozf/in [N/25.4mm]) | Moisture permeability (g-mil/m2-day) |

|---|---|---|---|---|---|---|---|---|---|---|

| ARcare® 93691 | Acrylic PSA for adhering medical devices to skin tapes | DCT | White polyester / 51 μm | “Acrylic skin / 41 μm” | White non-woven scrim | “Acrylic device / 33 μm” | Clear polyester / 76 μm | 78 (21.7) | 90 (25.0) | 200 |

| ARcare® 94180 | Acrylic PSA for adhering medical devices to skin tapes | DCT | White polyester / 51 μm | “Acrylic skin / 64 μm” | White non-woven scrim | “Acrylic skin / 64 μm” | Clear polyester / 51 μm | 49 (13.6) | 77 (21.4) | 220 |

| ARcare® 93551 | Acrylic PSA for adhering medical devices to low surface materials | TT | Clear polyester, easy release / 51 μm | Acrylic skin / 28 μm | – | – | Clear polyester, medium release / 51 μm | 65 (18.1) | – | – |

Device Assembly

| Product | Description | Construction | Viscosity, cPs | Lap sheer | Refractive index |

|---|---|---|---|---|---|

| ARcare® 93691 | UV curable liquid adhesive for bonding medical devices with multiple-substrates | UV curable liquid adhesive | 5000-8000 | ~2000 | 1.51 |

Space Management

| Product | Description | Construction | 1st Release Liner (Type/Thickness) | 1st Adhesive (Type/Thickness) | Carrier/Backing (Color/Type/Thickness) | 2nd Adhesive (Type/Thickness) | 2nd Release Liner (Type/Thickness) | Peel Adhesion to Stainless Steel (ozf/in [N/25.4 mm]) | 2nd Adhesive Peel Adhesion to Stainless Steel (ozf/in [N/25.4 mm]) |

|---|---|---|---|---|---|---|---|---|---|

| ARcare® 7840 | Acrylic PSA for bonding, laminating and assembly of medical devices | DCT | Clear polyester / 51 μm | AS- 110 acrylic / 20 μm | White polyester / 51 μm | AS- 110 acrylic / 20 μm | Clear polyester / 51 μm | 70 (19.5) | – |

| ARcare® 8252 | Acrylic PSA for bonding, laminating and assembly of medical devices | DCT | Clear polyester / 51 μm | AS-110 acrylic / 41.9 μm | Clear polyester / 25 μm | AS-110 acrylic / 41.9 μm | Clear polyester / 51 μm | 70 (19.5) | – |

| ARcare® 8939 | Acrylic PSA for bonding, laminating and assembly of medical devices | DCT | Clear polyester / 51 μm | “AS-110 acrylic / 25 μm” | White polyester / 76 μm | “AS-110 acrylic / 25 μm” | Clear polyester / 51 μm | 50 (13.9) | – |

| ARcare® 90445Q | Acrylic PSA for bonding, laminating and assembly of medical devices | DCT | Clear polyester / 51 μm | “AS-110 acrylic / 28 μm” | Clear polyester / 25 μm | “AS-110 acrylic / 28 μm” | Clear polyester / 51 μm | 70 (19.5) | – |

| ARcare® 92363 | Differnetial tape for bonding, laminating and assembly of medical devices with varying surface energies | DCT | Clear polyester / 51 μm | “AS-110 acrylic / 25 μm” | White polyester / 76 μm | “MA-70 rubber / 33 μm” | Clear polyester / 51 μm | 150 (41.7) | 84 (23.4) |

| ARcare® 8914-6970 | Acid-free, ultra-low outgassing acrylic PSA for use in medical applications | DCT | Clear polyester / 51 μm | “AS-139 acrylic / 38 μm “ | White polyester / 51 μm | “AS-139 acrylic / 38 μm” | Clear polyester / 51 μm | 65 (18.1) | – |

| ARcare® 8915-6970 | Acid-free, ultra-low outgassing acrylic PSA for use in medical applications | DCT | Clear polyester / 51 μm | “AS-139 acrylic / 38 μm “ | Clear polyester / 76 μm | “AS-139 acrylic / 38 μm” | Clear polyester / 51 μm | 60 (16.7) | – |

| ARcare® 8915W-6970 | Acid-free, ultra-low outgassing acrylic PSA for use in medical applications | DCT | Clear polyester / 51 μm | “AS-139 acrylic / 38 μm “ | White polyester / 76 μm | “AS-139 acrylic /38 μm “ | Clear polyester / 51 μm | 60 (16.7) | – |

| ARclean® 90176 | Acid-free, low outgassing acrylic PSA for use in medical applications | DCT | Off-white paper/ 84# / 160 μm | AS-144 acrylic / 38 μm | Clear polyester / 51 μm | AS-144 acrylic / 38 μm | Clear polyester / 51 μm | 55 (15.3) | – |

| ARcare® 92660 | High tack, shear and adhesion acrylic PSA for medical device assembly. | DCT | Clear polyester / 51 μm | AS-203 acrylic / 38 μm | “White polyester / 178 μm “ | AS-203 acrylic / 38 μm | Clear polyester / 51 μm | 85 (23.6) | – |

| ARcare® 93836 | Acrylic PSA for bonding, laminating and assembly of medical devices | DCT | Clear polyester / 51 μm | AS-342 acrylic / 20 μm | Clear polyester / 51 μm | AS-342 acrylic / 20 μm | Clear polyester / 51 μm | 45 (12.5) | – |

| ARcare® 90106NB | High tack and peel adhesion acrylic PSA ideally suited for bonding, laminating and assembly of low surface energy medical device components | DCT | White polyester / 51 μm | “MA-69 acrylic / 58 μm” | Clear polyester / 25 μm | “MA-69 acrylic / 58 μm” | White polyester / 51 μm | 150 (41.7) | – |

| ARcare® 92848 | Thermoplastic, heat sealing adhesive for joining of polymer plastic and metalized plastic substrates in medical devices | HDCT | Clear polyester / 51 μm | MA-77 heat seal / 23 μm | White polyester / 51 μm | MA-77 heat seal / 23 μm | Clear polyester / 51 μm | – | – |

| ARcare® 92712 | Flexible, thin, conformable acrylic adhesive for bonding, laminating and assembly of medical devices | DCT | Clear polyester / 51 μm | “MA-78 acrylic / 18 μm” | Clear polyester / 13 μm | “MA-78 acrylic / 18 μm” | Clear polyester / 51 μm | 66 (18.3) | 67 (18.6) |

| ARcare® 94119 | Silicone PSA evaporation barrier for bonding, laminating and assembly of medical devices | DCT | Clear polyester / 51 μm | “SR-29 silicone / 46 μm” | “Clear polypropylene / 51 μm” | “SR-29 silicone / 46 μm” | Clear polyester / 51 μm | 65 (18.1) | – |

| ARcare® 7737 | High tack self-would tape for bonding, laminating and assembly of medical devices | DCT | Off-white paper/ 55# / 81 μm | Acrylic / 33 μm | Clear polyester / 25 μm | Acrylic / 33 μm | – | 91 (25.3) | – |

| ARcare® 92448 | Rubber PSA for bonding, laminating and assembly of medical devices | DCT | Clear polyester / 51 μm | Rubber / 76 μm | Clear polyester / 250 μm | Rubber / 76 μm | Clear polyester / 51 μm | 198 (55.0) | – |

Conductive Bonding

| Product | Description | Construction | 1st Release Liner (Type/Thickness) | 1st Adhesive (Type/Thickness) | Carrier (Color/Type/Thickness) | 2nd Adhesive (Type/Thickness) | 2nd Release Liner (Type/Thickness) | Peel Adhesion to Stainless Steel (ozf/in [N/25.4 mm]) | Volume Resistance | Surface Resistance |

|---|---|---|---|---|---|---|---|---|---|---|

| ARcare® 90615 | Acrylic conductive nonwoven PSA for bonding, laminating and assembly | DCT | Double-sided white paper / 94# / 152 μm | Electrically conductive acrylic / 51 μm | Electrically conductive non-woven / 20 μm | Electrically conductive acrylic / 51 μm | – | 45 (12.5) | ≤ 3 mΩ | 11 Ω/sq |

| ARcare® 8881 | Acrylic conductive nonwoven PSA for bonding, laminating and assembly | DCT | Double-sided white paper / 94# / 152 μm | Electrically conductive acrylic / 51 μm | Electrically conductive non-woven / 20 μm | Electrically conductive acrylic / 51 μm | – | 70 (19.5)64 (17.8) | 3 Ω maximum | 6-8 Ω/sq |

| ARcare® 8874 | Acrylic conductive nonwoven PSA for bonding, laminating and assembly | DCT | Clear polyester / 51 μm | Electrically conductive acrylic / 46 μm | Electrically conductive nonwoven / 20 μm | Electrically conductive acrylic / 46 μm | “White paper / 55# / 81 μm” | 52 (14.5) | – | 3.7 Ω/sq |

| ARcare® 90366 | Acrylic conductive nonwoven PSA for bonding, laminating and assembly | TT | Double-sided clear polyester / 51 μm | Electrically conductive acrylic / 33 μm | – | – | – | 25 (7.0) | 10 Ω maximum | – |

Process Aids

| Product | Description | Construction | Carrier (Color/Type/Thickness) | Adhesive (Type/Thickness) | Peel Adhesion to Stainless Steel (ozf/in[N/25.4 mm]) | Release Classification | Release Force (g/2in) |

|---|---|---|---|---|---|---|---|

| ARclad® 79027 | Low-tack acrylic self-wound tape suitable for temporary protection or as a process aid for casting | SCT | Clear polyester / 51 μm | Acrylic / 18 μm | 0.3 (0.08) | – | – |

| ARclean® W-5029 | Clean liner with low extractables | SCT / Liner | Clear polyester / 51 μm | – | – | Tight | 100 |

| ARclean® W-5030 | Ultra-clean liner with ultra-low extractables; Ideal for sensitive medical and electrical components | SCT / Liner | Clear polyester / 51 μm | – | – | Medium-tight | 54 |

| ARclean® W-5047 | Thermally cured, solventless, silicone liner suitable for clean and consistent removal of liner from adhesive and cast materials | SCT / Liner | Clear polyester / 51 μm | – | – | Easy | 15 |

| ARclean® W-5048 | Thermally cured, solventless, silicone liner suitable for clean and consistent removal of liner from adhesive and cast materials | SCT / Liner | Clear polyester / 51 μm | – | – | Medium-tight | 50-70 |

| ARclean® W-5049 | Thermally cured, solventless, silicone liner suitable for clean and consistent removal of liner from adhesive and cast materials | SCT / Liner | Clear polyester / 51 μm | – | – | Easy-medium | 25 |

| ARclean® W-5051 | Thermally cured, solventless, silicone liner suitable for clean and consistent removal of liner from adhesive and cast materials | SCT / Liner | Clear polyester / 51 μm | – | – | Tight | 70-130 |

| ARclean® W-3361 | Low extractable silicone liner suitable for applications that require practically zero extractable silicone | SCT / Liner | Clear polyester / 38 μm | – | – | Easy-medium | 30 |

| ARclean® W-3362 | Silicone liner suited as a secondary or lay-in liner in medical applications | SCT / Liner | Clear polyester / 51 μm | – | – | Easy-medium | ≤ 40 |

| ARclean® W-3363 | Fluorosilicone liner suited as a secondary or lay-in liner in medical applications | SCT / Liner | Clear polyester / 51 μm | – | – | Easy-medium | 24 |

| ARclean® W-3473 | Clean, low extractables, silicone liner. Formulated and with the smoothest surface and high thickness consistency | SCT/Liner | Clear polyester/ 51 μm | – | – | Easy | 22 |

| Column 1 Value 13 | Clean, low extractables, silicone liner. Formulated and with the smoothest surface and high thickness consistency | SCT/Liner | Clear polyester/ 51 μm | – | – | Medium-tight | 60 |

Let’s Discuss Your Requirements