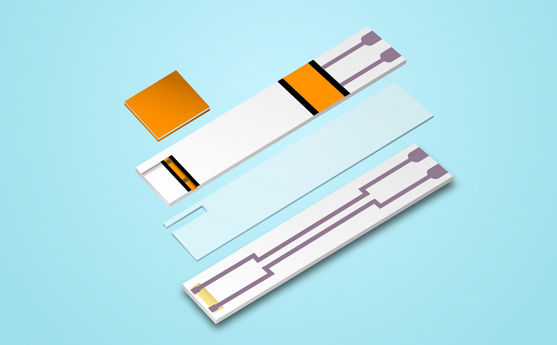

Pressure sensitive adhesives (PSA) are one of the key components of a diagnostic device, especially in many disposable IVD and biosensors. PSA offers precise and accurate bond lines that improve the reproducibility of these devices and facilitate an efficient manufacturing process. Tight thickness control of PSA is the key contributing factor in the success of lateral flow assay and microfluidic IVD devices. Since the height of the capillary channel is vital for accurate test readings, maintaining tight thickness tolerances of PSA used in bonding or laminating is crucial for the overall performance and functionality of the device.

Adhesives Research (AR) provides custom formulations and process controls that enable device manufacturers to set a universal calibration code for their product lines. From raw material selection, viscosity control, online coating controls and off-line monitoring, AR can maintain adhesive tolerances of +/ – 1 micron. These tight tolerances allow for higher yields and accuracy, saving manufacturers significant time and money during scale up and production, as well as consistent results for end users.

In a recent business example, a medical device company contacted AR for a chemically inert and thickness controlled adhesive for test strip assembly for use in their ultra-low volume blood glucose testing. Our expert team of scientists and engineers provided a chemically and environmentally stable double-sided PSA with adhesive thickness tolerance of +/- 1.5 micron. With this achievement we helped the customer launch the product and gain a significant market share within 12 months.

Adhesives Research is a leading adhesive manufacturer and your only partner providing adhesive design flexibility, and fast development capabilities for diagnostic devices. To discuss your custom adhesive requirements contact Adhesives Research at marketing@arglobal.com